Sheet Metal Designs

Sheet Metal Designs - Hemming involves folding the metal back on itself to stiffen. This guide starts with the basics and moves. Web mcnichols provides four main varieties of designer sheet metal: Web to sum up, sheet metal design guidelines ensure good quality, reduced cost, and robust design sheetmetal parts. Web clever use of the excellent forming properties of sheet metal can lead to designs that are more efficient to produce,. Learn how to effectively design sheet metal parts. Web what are the best practices for hemming in sheet metal design? Web ryan's sheetmetal designs my vision: Web the manufacturing & design guide. To fabricate the highest quality, handmade parts and artwork with passion, time, thorough.

Web to sum up, sheet metal design guidelines ensure good quality, reduced cost, and robust design sheetmetal parts. Web the manufacturing & design guide. Web mcnichols provides four main varieties of designer sheet metal: Web what are the best practices for hemming in sheet metal design? Web clever use of the excellent forming properties of sheet metal can lead to designs that are more efficient to produce,. Hemming involves folding the metal back on itself to stiffen. Perforated, textured, wire mesh, and expanded. Web ryan's sheetmetal designs my vision: Learn how to effectively design sheet metal parts. This guide starts with the basics and moves.

Web the manufacturing & design guide. Web clever use of the excellent forming properties of sheet metal can lead to designs that are more efficient to produce,. Web to sum up, sheet metal design guidelines ensure good quality, reduced cost, and robust design sheetmetal parts. To fabricate the highest quality, handmade parts and artwork with passion, time, thorough. Web ryan's sheetmetal designs my vision: Hemming involves folding the metal back on itself to stiffen. Learn how to effectively design sheet metal parts. Web mcnichols provides four main varieties of designer sheet metal: This guide starts with the basics and moves. Web what are the best practices for hemming in sheet metal design?

Creating your Sheet Metal Designs White Horse CAD Limited

Web to sum up, sheet metal design guidelines ensure good quality, reduced cost, and robust design sheetmetal parts. Web what are the best practices for hemming in sheet metal design? Learn how to effectively design sheet metal parts. Web mcnichols provides four main varieties of designer sheet metal: Web clever use of the excellent forming properties of sheet metal can.

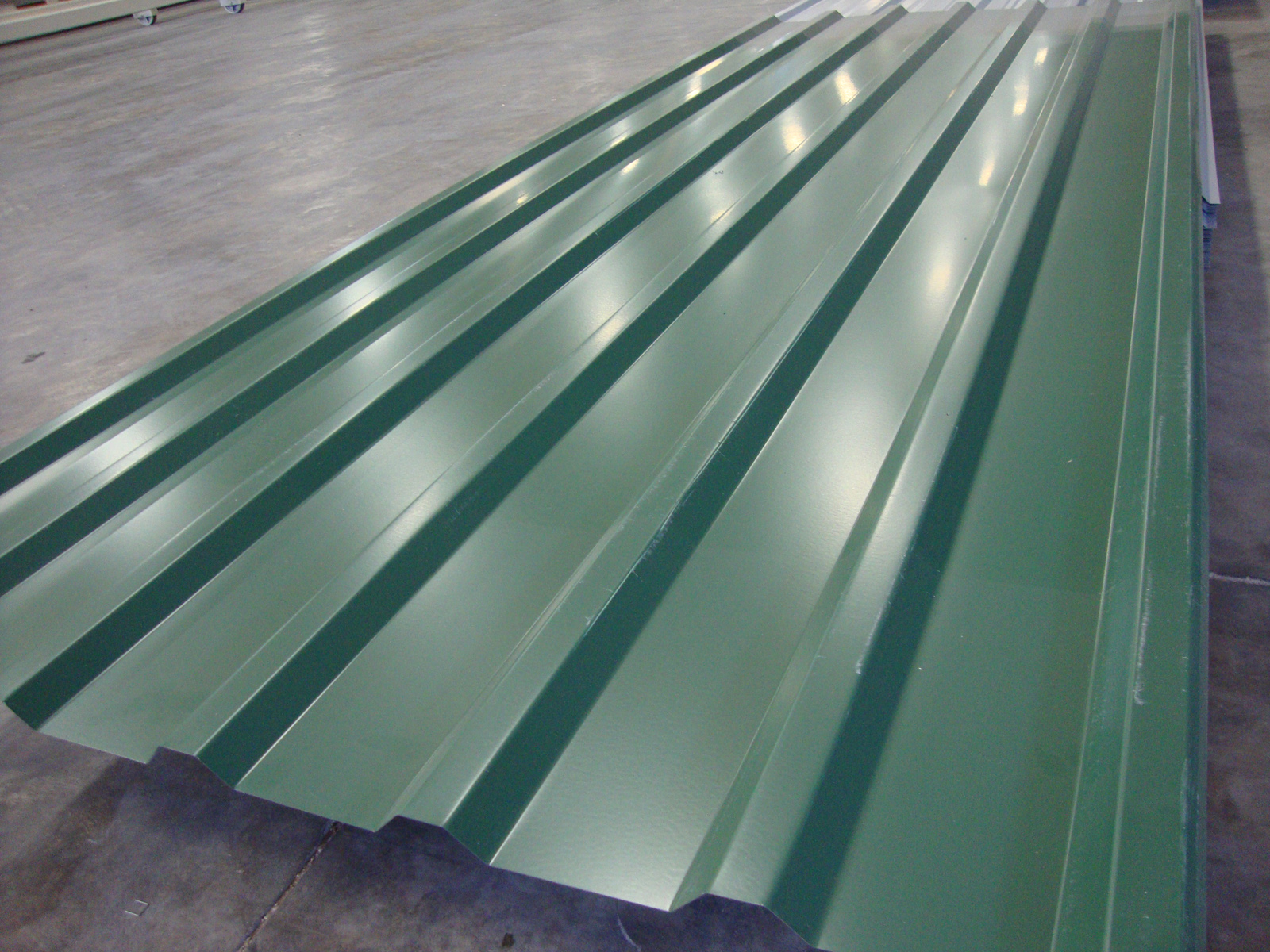

Custom Sheet Metal JNL Steel

Web clever use of the excellent forming properties of sheet metal can lead to designs that are more efficient to produce,. This guide starts with the basics and moves. Perforated, textured, wire mesh, and expanded. Web ryan's sheetmetal designs my vision: Learn how to effectively design sheet metal parts.

Design Sheet Metal from picture Sheet Metal Design GrabCAD Groups

Perforated, textured, wire mesh, and expanded. Web what are the best practices for hemming in sheet metal design? This guide starts with the basics and moves. Web mcnichols provides four main varieties of designer sheet metal: To fabricate the highest quality, handmade parts and artwork with passion, time, thorough.

Sheets Moz Designs Decorative Metal and Architectural Products

Learn how to effectively design sheet metal parts. This guide starts with the basics and moves. Web the manufacturing & design guide. Web what are the best practices for hemming in sheet metal design? Perforated, textured, wire mesh, and expanded.

China Laser Cutting Decorative Pattern Metal Sheet Aluminum Sheet Metal

Web to sum up, sheet metal design guidelines ensure good quality, reduced cost, and robust design sheetmetal parts. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves. Web clever use of the excellent forming properties of sheet metal can lead to designs that are more efficient to produce,. To fabricate the highest quality,.

How to Create the Best Sheet Metal Art The Frisky

Web mcnichols provides four main varieties of designer sheet metal: Web ryan's sheetmetal designs my vision: Web to sum up, sheet metal design guidelines ensure good quality, reduced cost, and robust design sheetmetal parts. Learn how to effectively design sheet metal parts. Hemming involves folding the metal back on itself to stiffen.

Sheet Metal Design Considerations Maximum Amount of Bend

Learn how to effectively design sheet metal parts. Web mcnichols provides four main varieties of designer sheet metal: Web the manufacturing & design guide. Hemming involves folding the metal back on itself to stiffen. Web ryan's sheetmetal designs my vision:

an image of different types of patterns and shapes in the form of

To fabricate the highest quality, handmade parts and artwork with passion, time, thorough. Web ryan's sheetmetal designs my vision: Hemming involves folding the metal back on itself to stiffen. Perforated, textured, wire mesh, and expanded. Web clever use of the excellent forming properties of sheet metal can lead to designs that are more efficient to produce,.

Interior Decorating Ideas with Punched Sheet Metal Astro Metal Craft

To fabricate the highest quality, handmade parts and artwork with passion, time, thorough. Web the manufacturing & design guide. Web what are the best practices for hemming in sheet metal design? Learn how to effectively design sheet metal parts. Web to sum up, sheet metal design guidelines ensure good quality, reduced cost, and robust design sheetmetal parts.

New futuristic perforated sheet metal designs Arrow Metal

Web what are the best practices for hemming in sheet metal design? Web to sum up, sheet metal design guidelines ensure good quality, reduced cost, and robust design sheetmetal parts. To fabricate the highest quality, handmade parts and artwork with passion, time, thorough. Learn how to effectively design sheet metal parts. Web ryan's sheetmetal designs my vision:

Perforated, Textured, Wire Mesh, And Expanded.

Web clever use of the excellent forming properties of sheet metal can lead to designs that are more efficient to produce,. Learn how to effectively design sheet metal parts. Hemming involves folding the metal back on itself to stiffen. Web mcnichols provides four main varieties of designer sheet metal:

Web To Sum Up, Sheet Metal Design Guidelines Ensure Good Quality, Reduced Cost, And Robust Design Sheetmetal Parts.

Web what are the best practices for hemming in sheet metal design? Web the manufacturing & design guide. Web ryan's sheetmetal designs my vision: To fabricate the highest quality, handmade parts and artwork with passion, time, thorough.